Characterization of hydraulic knuckle

Experiments to characterize the performance of hydraulic knuckle

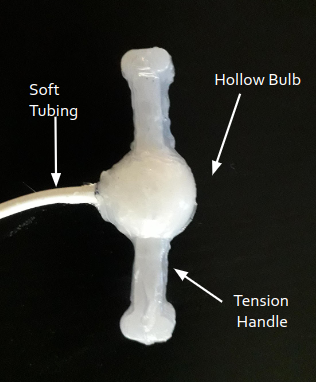

Hydraulic knuckles are hollow silicone bulb structures with tension handles on either sides manufactured using lost wax silicone molding process. A soft tubing is attached to connect the knuckles with a pressure control system. It is then covered with multiple layers of LDPE (low density polyethylene) sheets to prevent expansion during operation. The stiffness of the knuckles increases when it’s pressurized with water.

The performance of these knuckles in their active state was characterized under tension and compression to study the change in stiffness with change in starting internal pressure. Refer to the paper for the details of the manufacturing process, pressure control circuit and the experimental setup and results.

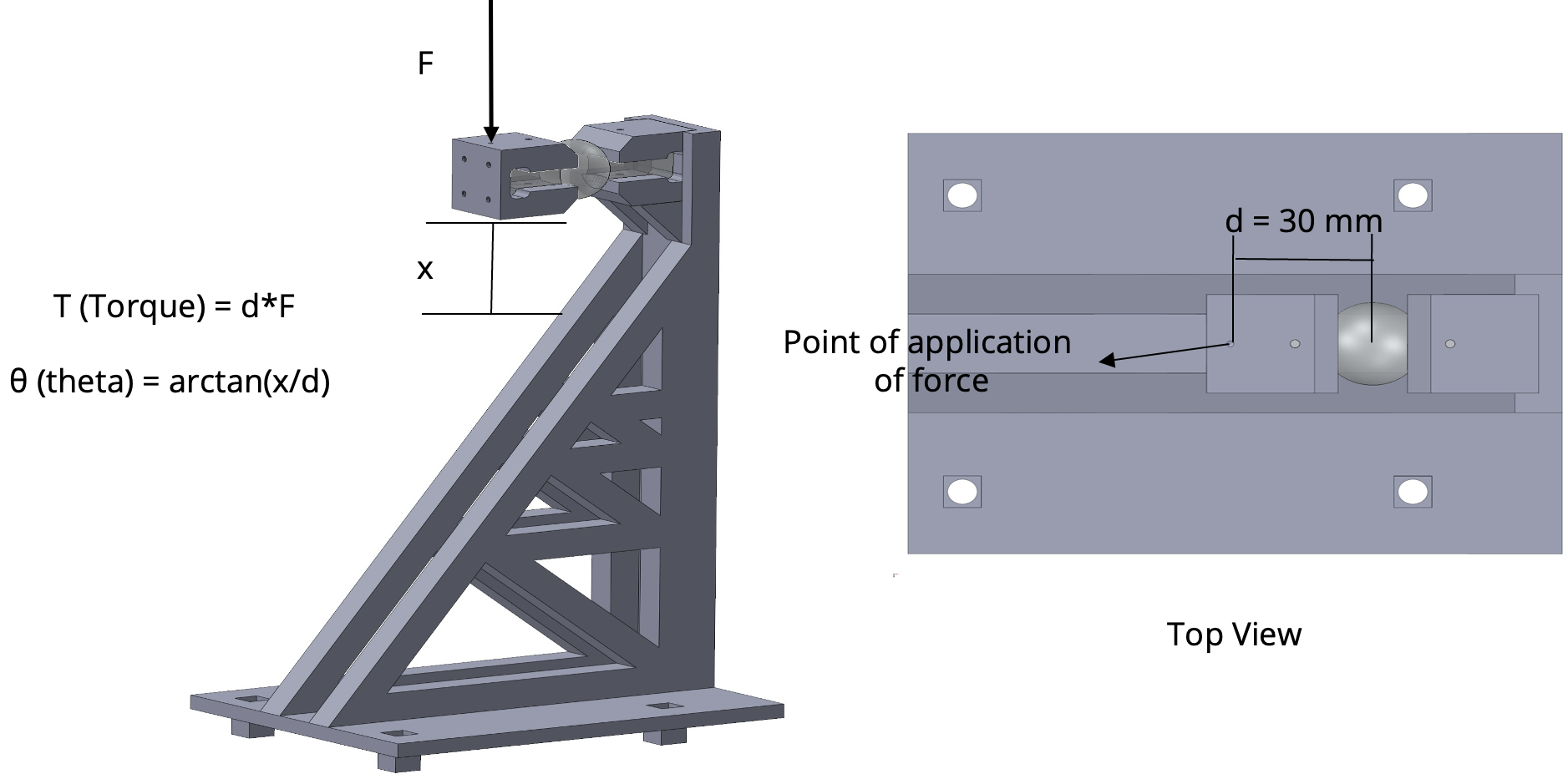

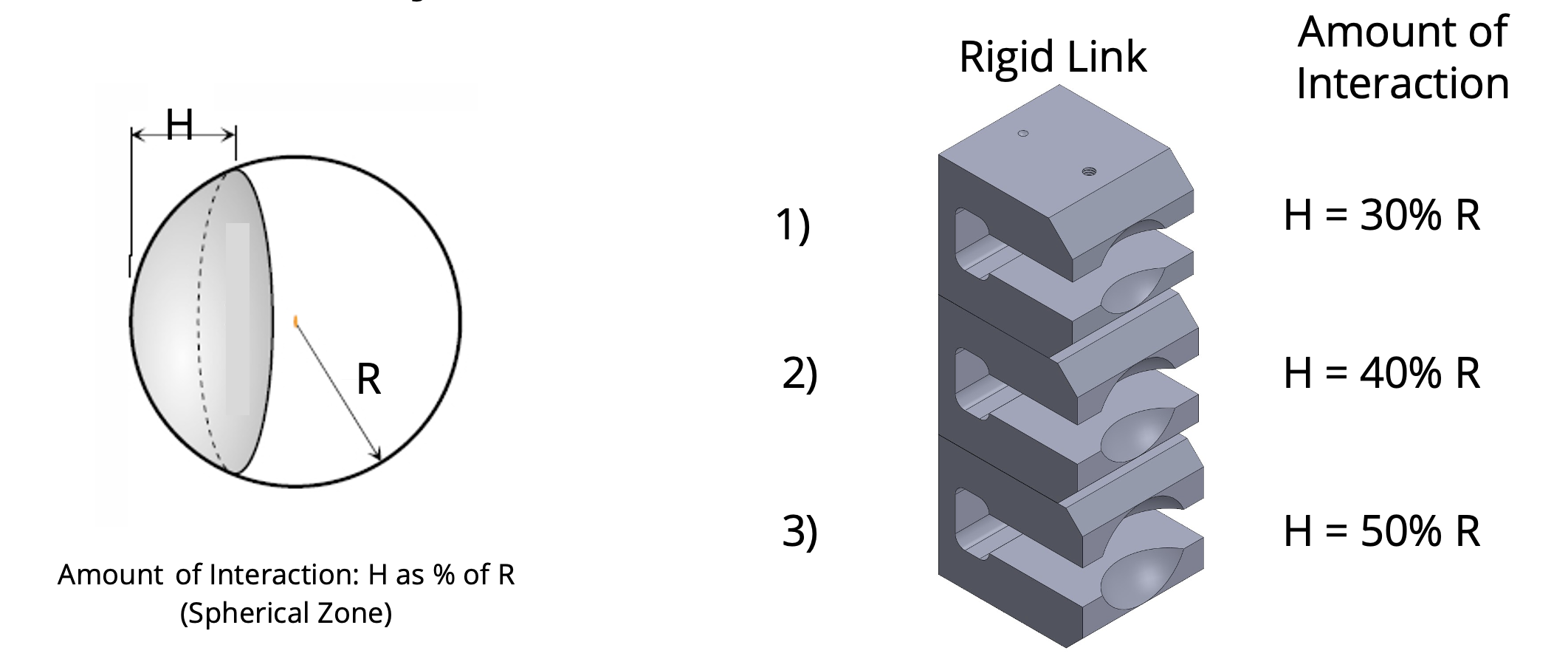

Furthermore, to study the effect of interaction between the hydraulic knuckle and a rigid link over the rotational stiffness were studied at different starting internal pressures.